Big Moves at Ravenswood Gold

Structural Engineering traditionally involves the design of static structures that are fixed to the ground and designed to resist imposed actions. Once in a while a project comes along that requires us to think outside of the box as structural engineers and work with a team to do something truly unique and special.

Over the last 12 months Bligh Tanner has had the opportunity to explore and develop creative solutions to preserve our heritage through the development of structural solutions to facilitate the relocation and preservation of 3 masonry chimneys.

The one hundred year old chimneys, Grant and Sunset, General Grant and Deep Mine and Mill were all positioned within the footprint of the proposed new Ravenswood Gold Open Pit and were approved for demolition after close consultation with the Department of Environment and Science (Other chimneys within Ravenswood have been refurbished and restored by Ravenswood Gold).

Photo 1: Deep Mine Chimney Prior to Relocation

Although the Chimneys were approved for demolition, Ravenswood Gold expressed a desire to undertake this work as conscientiously as possible to meet or exceed local and community expectations.

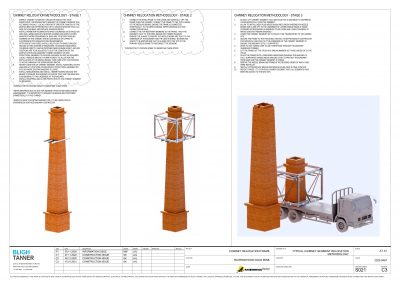

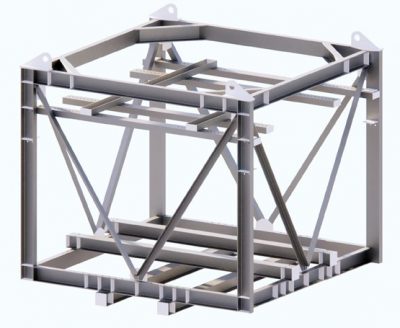

Through close consultation with Ravenswood Gold, DES, and in conjunction with Mozbiz – heritage masonry experts, Bligh Tanner developed a detailed methodology and lifting frame which could be used to lift chimney segments up to 10T in weight and 4m in height.

Figure 1: Detailed Lifting Methodology Drawing

Extensive Safety in Design and Workplace Health and Safety processes, reviews and meetings were undertaken to ensure the complex task was undertaken within the rigid safety standards Ravenswood Golds WH&S policy’s require.

The beauty of Bligh Tanner’s design and lifting frame is that the single frame was able to be adjusted and used for all 3 chimneys despite the geometry and configuration of each one differing substantially. (Refer Figure 2)

Figure 2: Chimney Lifting Frame

The site methodology involved a three-step process whereby large cracks and damaged masonry were repaired and restored. Ancon HeliBars and DryFix anchors were installed to strengthen the base of each segment that was to be lifted. The next step involved careful preparation of the chimney to install the needle-beams and recesses to accommodate the lifting steel. This work was completed by Maurie Potrzeba and his heritage masonry team from Mozbiz. The final stage involved the installation of the lifting cage over the chimney and connection of the lifting beams to enable the chimneys to be safely lifted.

Relocation of the chimney segments involved a team of 20 people including, Heritage Masons (Mozbiz), Scaffolders, Riggers and Crane and truck operators working closely together to facilitate the move safely. The concentration and intensity of the operation and team was very high during the first lift, however the methodology, operation and lift frame exceeded the expectations of the team and the operation was completed safely and successfully.

Photograph 2: Lifting frame being connected to the lifting beams

Photograph 3: The First Chimney Segment being lifted onto the Truck

Photograph 4: Associate Director and Lead Designer Simon Kochanek standing beside the first lift

Bligh Tanner has had great pleasure in having the opportunity to develop and provide engineering services for what has been a very satisfying and successful operation to preserve some of Australia’s Heritage. We would like to thank Ravenswood Gold for the opportunity to think outside of the box and for being willing to take on this ambitious project. We have also thoroughly enjoyed working closely with Mozbiz – Heritage Masons in developing some of the masonry techniques used in successfully lifting the chimney segments.

Please contact Simon Kochanek, Associate Director with any enquiries about heritage preservation and lifting.