Coral Aggregate Concrete for Pacific Islands

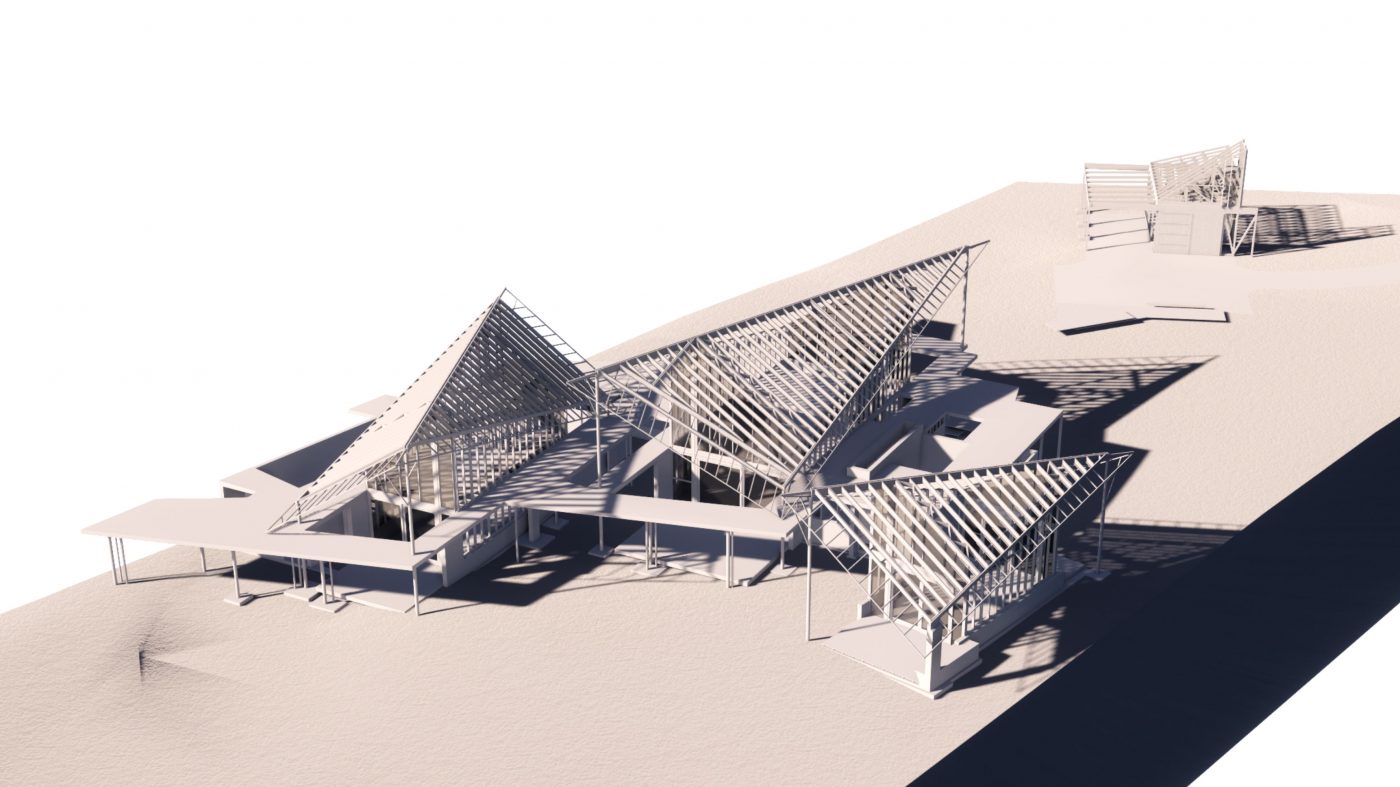

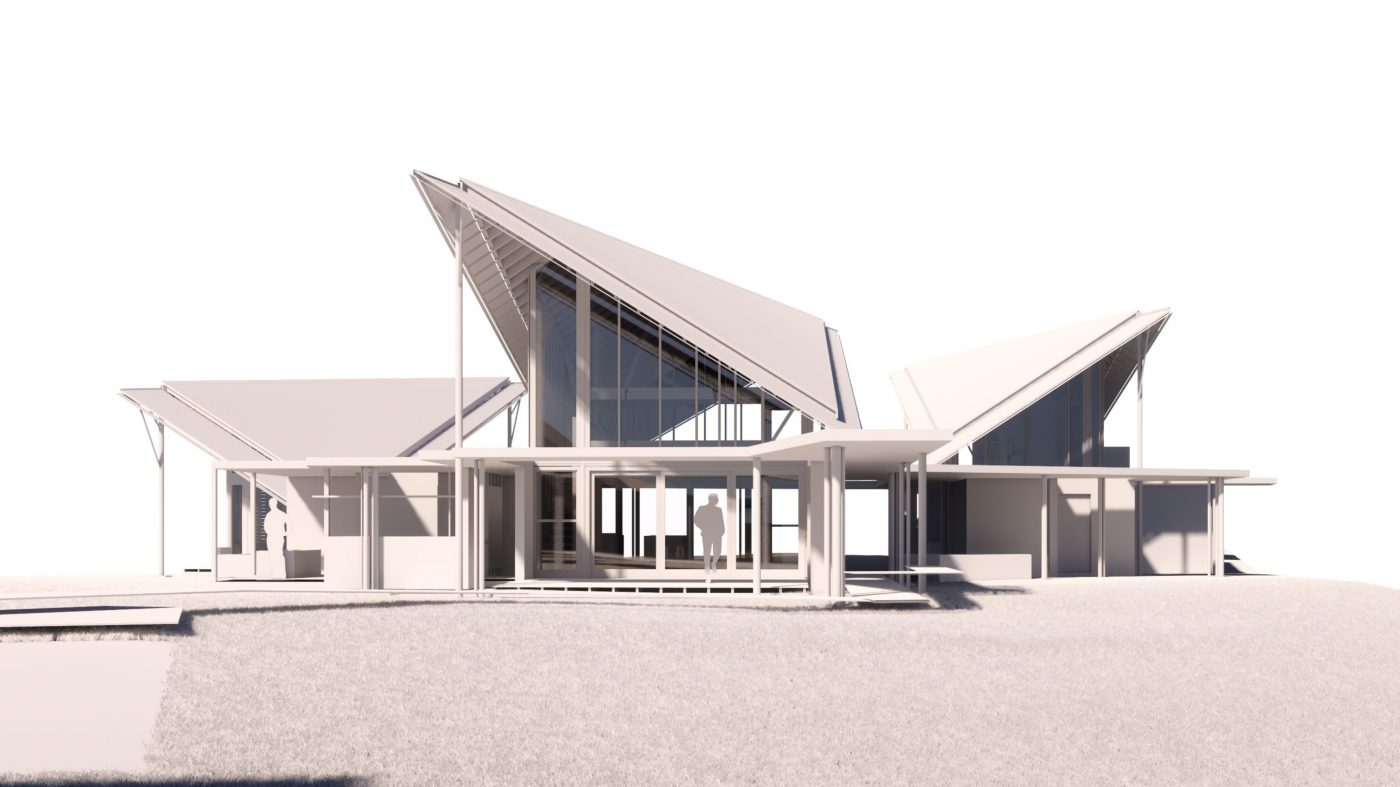

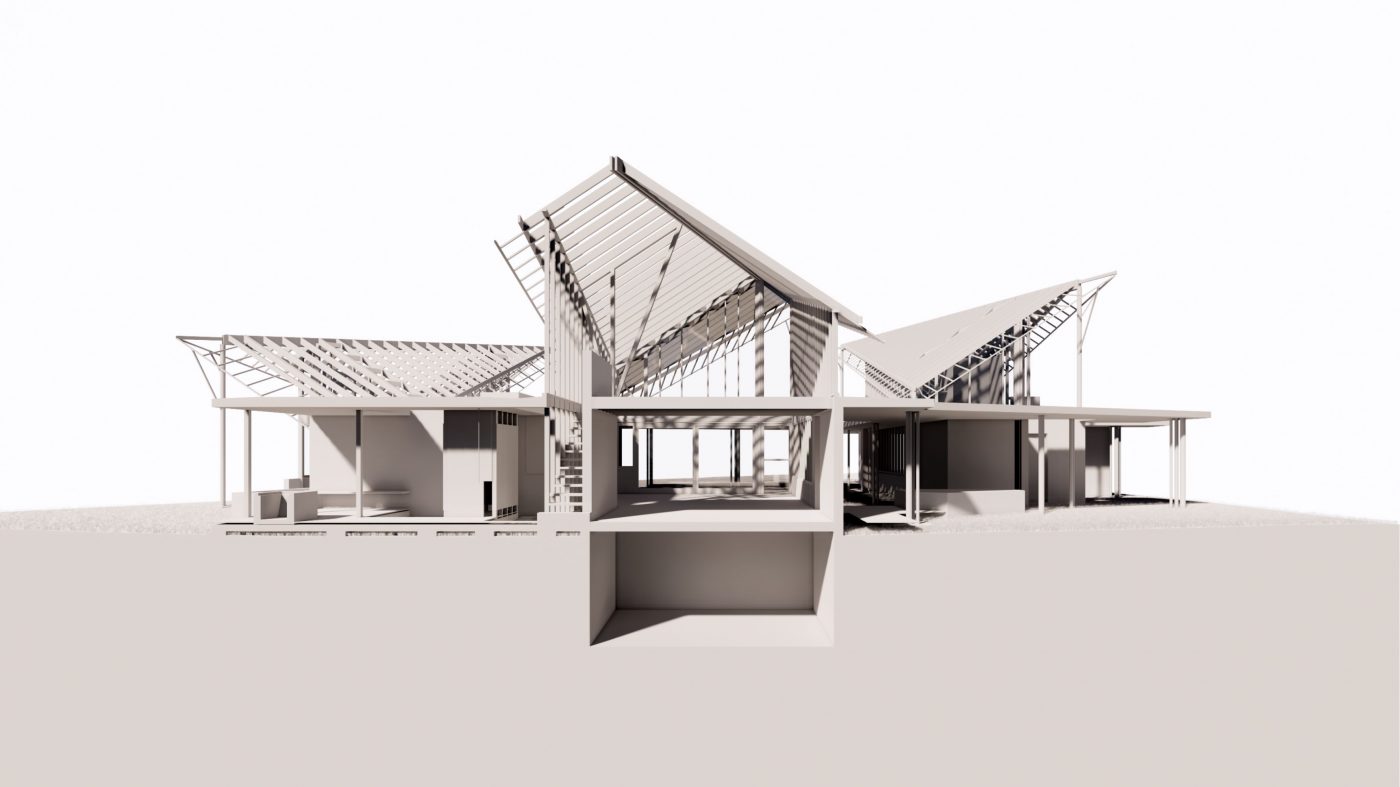

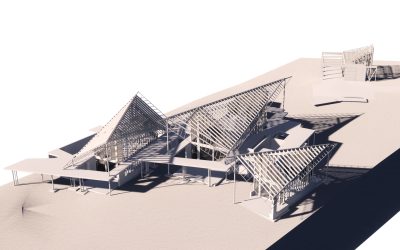

Designing a magnificent house on the island Espiritu Santo in Vanuatu with Tim Bennetton Architects has presented many challenges , not least being the specification of concrete made from the local coral aggregates and sands. Research indicated surprisingly sparse information limited to some second world war studies. The local builders who site mix concrete from raw materials and imported cement were only able to offer us their ‘strong’ and ‘regular’ mixes with no information on tested strength. The house included suspended concrete slabs and columns that also performed a critical function to stabilise the structure in cyclone and earthquake events , so achieving a durable product with reliable strength was imperative.

The first step was to bring some cylinders of site batched ‘strong’ mix back to Brisbane and have them tested at QUT. The test strength was 27.5MPa and the failure mode was shearing through the relatively weak and porous coral aggregates which indicated that achieving higher strengths was not likely. The ‘strong’ mix already had a high proportion of cement which was of concern for excessive shrinkage and crack potential , reducing durability. A decision was made to engage Dr Tatheer Zahra of QUT to develop an optimum mix to achieve 25MPa strength with reduced cement content. Dr Zahra’s research indicated that reducing coral aggregate quantities and increasing sand proportion may be an effective way to achieve this desired outcome.

Samples of coral aggregate and sand from Vanuatu were measured and tested at QUT to enable a mix design to be developed. Test cylinders of the mix design were then produced in Vanuatu and delivered back to Australia (in Paul Callum’s holiday suitcase) . Testing at QUT successfully confirmed the design 25MPa strength – a substantial achievement considering the absence of research or information on coral aggregate concrete. Cement content was able to reduced significantly with consequent financial and environmental benefits and improved durability with reduced shrinkage cracking potential.

The research paper written by Dr Tatheer Zahra is available here.

Images courtesy of Tim Bennetton Architects